Discover iTRAK® - The Intelligent Track System

Revolutionary New Capabilities

The iTRAK® Intelligent Track System presents an opportunity to revolutionize machine design in a way not seen in decades. Watch the way machine designs have changed from mechanical line shafts to electronic line shafts and finally to independent mover technology. This video shows how the mixture of continuous and intermittent motion, direct drive motion control, and high performance servo control can combine to increase the throughput, reduce changeover time, and reduce overall machine footprint.

Automated Assembly

The iTRAK® Intelligent Track System is a flexible replacement for precision link conveyors, providing greater flexibility with reduce machine floor space. This example shows how single piece flow can be queued and converted to batch processes, and back to single piece flow. Coordination with external processes such as glue gun is shown as well.

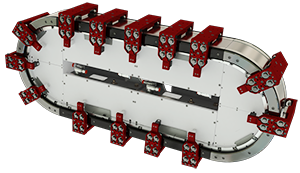

What Makes an iTRAK® System

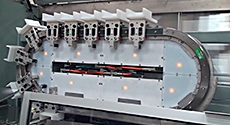

The iTRAK® Intelligent Track System is composed of components including curvilinear motors with integrated drives and feedback, movers, bearing rails, and mechanical structures. Movers can be synchronized to each other or operated independently. The components can be combined to create different shapes and mounted in multiple configurations. The components are also scalable, with many force-speed curves available.